Marty Ryan is skeptical that meatpacking companies are doing everything possible to mitigate the spread of COVID-19, based on two decades of experience in that business. -promoted by Laura Belin

Anyone believing that spokespersons for Iowa packing plants are doing what they say they are should talk to the employees. However, if you get two different stories, and if you want to decide who is telling the truth, place about 80 percent of the truth on the side of the worker.

I can say this with authority. In 1968, I went to work at Iowa Beef Packers in South Sioux City, Nebraska. I worked on the kill floor for about nine months.

After my stretch of military service, and a year or two working heavy equipment construction, I became employed by Farmland Foods in Denison, Iowa. I worked there for seventeen years. The cut floor was my first stop. Then I moved to the fabrication department. Finally, I became a sausage maker for most of my time at the plant.

However, during layoffs, and the ability to bump employees with less seniority, I was able to work night cleanup, pickle maker (the person who mixes salt, water, sugar, etc. to make brine for bacon, hams, etc.), loading dock, kill floor, bacon line, and several other jobs within the plant.

People on the floor know what’s going on and most likely know what to do in order to get more production, better quality, and a savings of resources.

One Friday night, while having a few beers with my co-workers, our department’s project manager came into the bar with the plant manager. They sat down with us at our table. A few beers into our conversation I had told the plant manager that within a two-week learning period, “I could perform every job in that plant as good as the person doing it now, including [the plant manager].” He got a big chuckle out of that. I still believe it.

The Monday after our after-work gathering, I saw the plant manager walking down one of the long hallways. He smiled and waved at me. I pulled him aside. I said, as humbly as I could, “I must make an apology for what I said last Friday night.” He looked down on me (he was tall) and told me that “it’s all right.”

“Yeah,” I said. “I could never be the plant electrician. I’m scared to death of electricity.” I turned and went on my way. We became pretty good friends.

Not only did I work in those two packing plants, but in 1984 I became a Union Secretary-Treasurer and business agent for United Food & Commercial Workers Union Local 440 in Denison. I represented several packing and processing plants in western Iowa. I visited each of those plants and was able to talk to many employees while they were working on the line. I spoke to them in their locker rooms and cafeterias, if they had one.

Asymptomatic carriers

For a meat packer to say that it “is taking precautions to protect its employees” means that the bare minimum is being done to keep that line moving without interruption, and that the only way to do that is to make sure there are enough bodies to keep that line running fast. The primary goal of meatpackers is to make a profit. I can attest to that fact based on numerous contract negotiations held with company attorneys and managers.

Taking temperatures of workers as they arrive to work is health care theater. Not all people with COVID-19 run a fever. A regular temperature of an employee will not indicate whether the employee is in an incubation period. From a Business Insider report earlier this month:

According to Robert Redfield, the director of the Centres for Disease Control and Prevention, 25 percent of people infected with the new coronavirus don’t present any symptoms or fall ill but can still transmit the illness to others.

Asymptomatic people are carrying a disease or infection without showing any of the symptoms usually associated with that condition.

Masks or shields

Protective face coverings? Describe it. Wearing a hard hat is hot enough in a slaughter environment. To include wearing a protective face covering, whatever that means, may not improve safety, especially if the worker needs to wear glasses, whether safety glasses or glasses to see. Perspiration coming down from the helmet is going to soak up the face-covering.

Logically, a protective face-covering could be a large handkerchief, an N95 face mask, or a plastic shield. If doctors and nurses are having a difficult time getting personal protective equipment (PPE), why are packing houses supposedly having no problem?

While employees on kill floors work in hot conditions, those working in other areas of a meatpacking plant often get colds. On a cutting floor, or in processing, boning, and other areas, the air temperature may be below forty degrees.

It’s difficult to take time off work when you have the sniffles, but if the cold or allergies are not draining the strength out of you, you can get by with blowing your nose during a lull in the line. Imagine doing that now that you have to remove protective face coverings.

Further, placing plastic shields between workers on a line will limit the mobility of each employee. Quality will suffer. Also, knives are an instrument for reaching out to pull a particle of meat back toward you as it moves down the line. Trust me; I have the scars. Some are self-inflicted; others were put there by my neighbors on the line.

When I was a union representative, I had ample proof that packing house work was the second most dangerous job. First place went to lumberjacks.

Allow me to interpret another recent quote I read from a Tyson Foods spokesperson. She said the company is “conducting additional cleaning and sanitizing.” Any firm in the meat business should always be conducting the utmost cleaning and sanitizing. That comment reeks of “we have people who were injured on the job, and are required by the company doctor to be performing light duty, (which is meaningless work designed to keep our workers compensation premiums as low as possible).”

Break rooms

I don’t know that I can speak generally about this problem, because it has been more than 25 years since I was in the meat business. The same Tyson spokesperson claimed that “where possible” the company is “providing more breakroom space”.

In all my travels throughout western Iowa, eastern Nebraska, and southeast South Dakota (Local 440 merged with District Local 271 out of Omaha and my territory was greatly expanded to Norfolk, NE; Mitchell, SD; LeMars, IA and several stops in between), I have yet to see a locker room, cafeteria, or break room large enough to allow for social distancing (6 feet) at any one time while a department is on break, getting ready for work, or changing to leave work. Take the phrase “where possible” with a grain of salt.

Governor Kim Reynolds said on April 16 that “state public health officials are ‘getting into these facilities’ and educating management as well as workers about safety and mitigation efforts.” I don’t doubt that. What I do doubt is that everything stays static after public health officials have left.

Vertical integration

I read that farmers are worried that there will be no outlet for their hogs to be slaughtered. Farmers? Not the farmers I used to know.

The following is from an article I wrote for The Prairie Progressive:

Smithfield Foods, which owns the Farmland Foods label as well as John Morrell, is owned by WH Group out of Hong Kong and slaughters 30 million hogs per year; JBS USA (formerly Swift) is a wholly owned subsidiary of JBS, a Brazilian company that also owns Pilgrim’s Pride chicken; and the third Big Pork is Tyson Foods, an American company known mostly for chicken, but slaughters hogs at their IBP locations.

All three of these companies are vertical integration food companies, meaning they own the operation from piglet to sow, and in some cases, own the entire farm, the packing and processing facilities, as well as the trucking and marketing companies to transport and sell their products. Often, these Big Pork companies contract with farmers to produce pigs, selling the pigs solely to the packer. Those farrowing houses you smell in the countryside are most likely owned by the multinational companies who employ their own personnel to manage them, and pay the farmer who owns the land rent each year or month for use of the land containing the hog raising facilities and waste lagoons. A farmer may also benefit from the manure produced by these operations.

JBS, with a plant in Worthington, MN, has been the recipient of $62 million in bailout money intended to supplement farmers hurt by the trade war. Joesley and Wesley Batista, the Brazilian owners of JBS, have admitted “to bribing hundreds of top officials in [Brazil] and have spent time in jail over the corruption scandal.”

The farmers with contracted hogs on their farms are caught in the middle of this situation. I sympathize with them. However, have the Big Pork companies done anything to mitigate their own loss by not breeding anymore sows for a while? Have they cut back? Have they closed down any breeding operations?

I would hate to see that pigs and their owners are more important than the people. It’s time to temporarily shutter the meat business in Iowa.

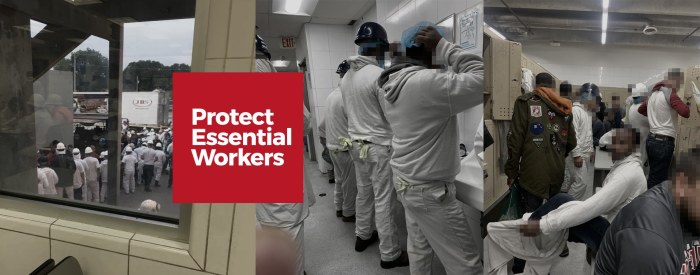

Top image: Photos published by the League of United Latin American Citizens, taken at the JBS pork processing plant in Marshalltown, Iowa on March 27, 2020. Shared on Facebook by Joe Henry of LULAC.

2 Comments

Excellent Information

I believe you. What should be done right now? Do the workers have union representation right now? What about the speeding up of meat production that was recently allowed by the Trump Administration? Has that contributed to the endangerment of workers? What’s up with all the undocumented workers? It seems to me that they should have special protected status, health care, union representation, etc., or the owners should be put in jail for hiring them. We either need them and treat them right, or we don’t.

EmilyatActivate Fri 17 Apr 7:57 PM

Marty please continue to keep us informed

Marty, Thanks for your reporting on the pandemic in Iowa from your unique perspective. It appears Gov. Reynolds is cooperating with the packing companies to hide the extent of spread of the virus among their employees. Residents of the communities where the plants are located deserve to be fully informed. Please help keep the public pressure on them.

miketram01 Sun 19 Apr 3:45 AM